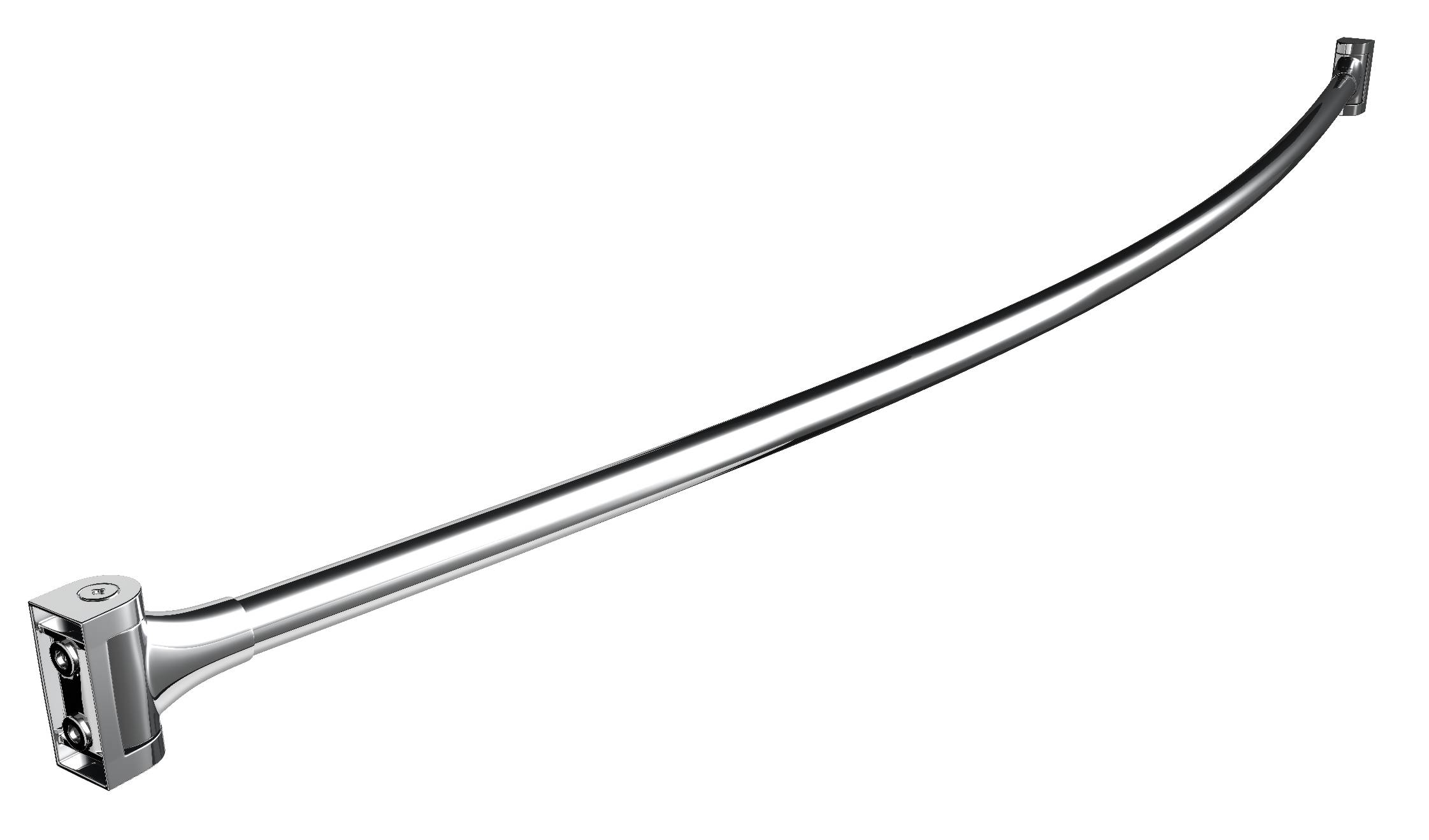

Stainless Steel 60” Curved Shower Rod

MSRP: $89.00 Distributors may sell for less

SPECIFICATIONS

Product Name: Stainless Steel 60” Curved Shower Rod

Single Carton UPC: 624622114503

Single Carton Shipping Dimensions: 162.6cm L x 27.9cm W x 12.7cm H (64” L x 11” W x 5” H)

Single Carton Shipping Weight: 1.4kg (3.0 lbs)

Site Location

Frost’s 1145-CRV 60” curved shower rods are often specified and designed for use in both commercial and residential settings. Typically, these are used in schools/universities, recreation centres, hospitals, hotels, fitness facilities, and long-term care homes.

Features

- Easy to install and maintain

- 60” shower rod length

- Shower rod and flanges are stainless steel

- Provides an elegant and practical use of space

Materials

- 1” diameter stainless steel rod with die cast stainless steel flanges. Brushed finish.

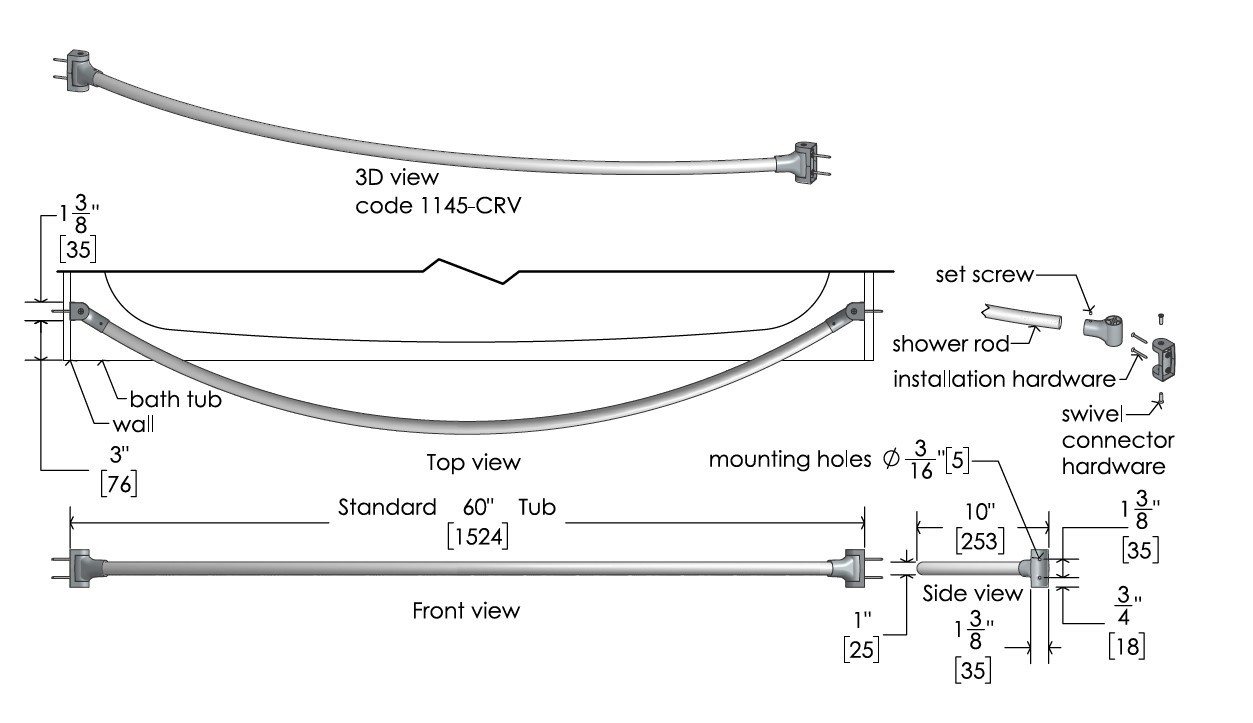

Product Dimensions

- 152.4cm L x 25.3cm W x 7.6cm H (60” L x 10” W x 3” H)

Product Weight

- 1.13kg (2.5 lbs)

Installation Guidelines

Assemble curved shower rod. Hand tighten retaining screws. Do not tighten set screws at this time. Measuring Placement: Hold rod up to desired position, one person at each end, to check height and location. Be sure that rod is level. With a pencil lightly trace the top and bottom of the wall plate. Set rod down. Remove retaining screws. Separate the wall plates from the rod. Leave swivel connectors on the rod. Place wall plates back on the wall at pencil marks. Mark screw holes at 12 and 6 o’clock positions. Set wall plate aside. Read anchor instructions carefully. Drill screw holes as marked. Install 4 anchors unless a hole is on a stud. Mount wall plates, Screw in to anchors. Place rod, with swivel connectors attached and set screw holes facing up into wall plates. Screw in retaining screws. Tighten. Adjust rod. Be sure that each end of rod is into the connector far enough to engage set screws and make solid contact. Tighten set screws with allen wrench. Helpful Hints: Put a drop of thread fastener such as silicone on each of the set screws and retaining screws to prevent them from working loose. If mounting above the tile line leave enough room to use screw driver on the bottom retaining screws.

Maintenance

Normal preventative maintenance and cleaning will keep Frost products functioning properly and may extend normal product life. Products should be wiped down with a damp soft cloth periodically. Approved stainless steel cleaner may be used to clean scuffs or fingerprints on stainless surfaces. Do not use harsh detergents or chemical cleaners. For stainless steel please do not spray with any product containing bleach, acids, or chlorides, which can be found in many cleaning products such as toilet bowl cleaners. Use of these cleaning solutions may cause discolouration and if used for prolonged periods of time they can eat away at points in the stainless steel. If discolouration occurs, the use of an approved stainless steel cleaner and a firmer scrub pad, such as a Scotch Brite Pad #7447, may remove the markings. Wipe away any debris from the area and gently rub with the pad. Then spray the area with a stainless steel cleaner/polish and rinse and dry. Always wipe with the grain direction for stainless steel products. If a cleaning agent has begun to eat away at the steel on a unit then the unit will likely need to be replaced. The stainless steel that Frost Products uses is of high quality and stainless steel is resistant to rust. However, discolouration that appears to be rust can be caused by cleaning solutions. It is important to discontinue use of any cleaning agent or soap if discolouration begins to occur. Clean off the discolouration as quickly as possible to avoid any permanent damage to the unit. Maintenance staff should be taught how to recognize the signs that they are not using the appropriate cleaning products and how to correctly maintain stainless steel items.

Warranty

If any product or part proves to be defective within 12 months from date of shipment from the factory it will be repaired or replaced without any charge including freight costs when authorized. Costs resulting from the installation or removal of defective products are not covered under this warranty. Discolouration to stainless steel parts resulting from exposure to harsh environmental and / or chemicals are not considered to be defects in workmanship or material and are not covered under warranty.

Additional Info and Downloads

|

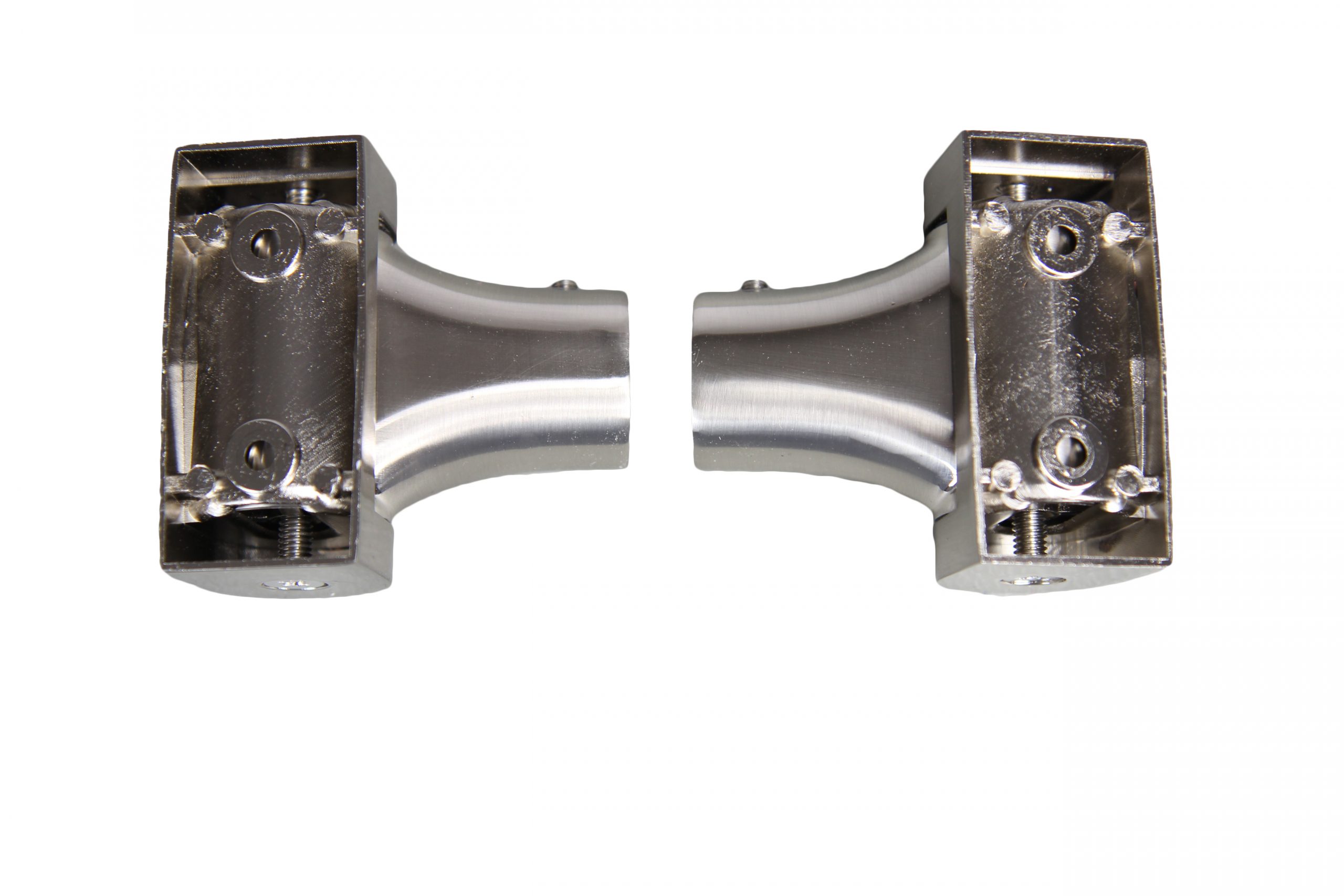

End brackets for 1145-CRV | CDN $35.00 |

|

|

||